IN FOCUS

You don't always see G&D's products and solutions right away.

But they are important elements and they work. Always! You can rely on G&D for quality that you can feel.

INSIDE G&D

01

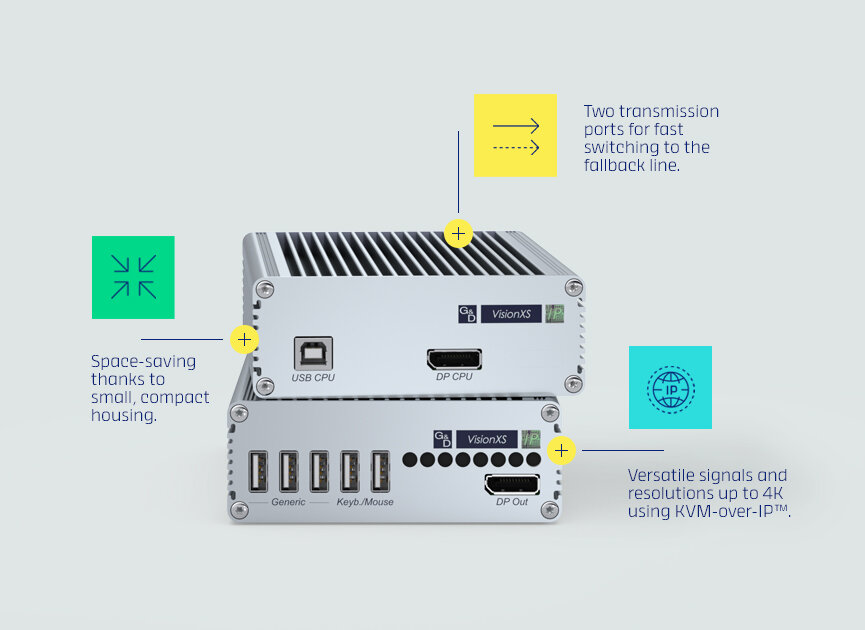

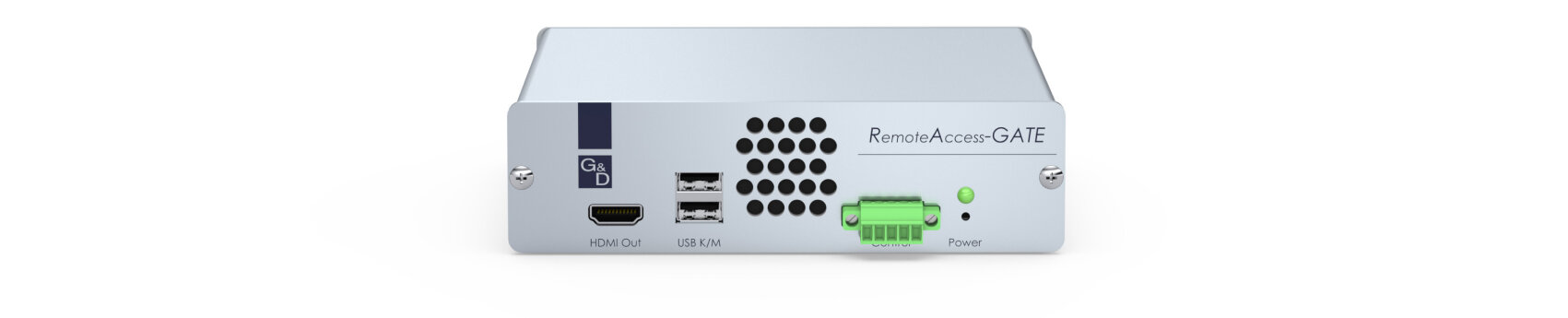

KVM solutions by G&D

Product highlights

G&D protects lives and businesses

With G&D, you can operate your systems safely, quickly, and in high quality over long distances. People working in control rooms can rely on G&D.

With KVM switches, KVM extenders and analog and digital matrix systems,

G&D provides security- and business-relevant solutions that protect lives and businesses.

KVM STORIES

CASE STUDIES

G&D Campus – feels like getting smarter.

Find everything you need to know about KVM technology, our products, product training, the latest events and simply a whole lot of knowledge.

Collection of technical terms and explanations.

To the glossary

Events

To all events

Questions and answers

To the Faq's

Videos from the world of KVM

To the Media library

KVM trainings by our experts

Overview

Knowledge on various topics

To the downloads

G&D Contact

The best way to talk about complex topics is in person. Via chat, e-mail, phone or in a personal demo

remote or on-site.

Your G&D Support We are

here for you - personally

and competently

Support overview

Copyright© 2024 G&D. All rights reserved.